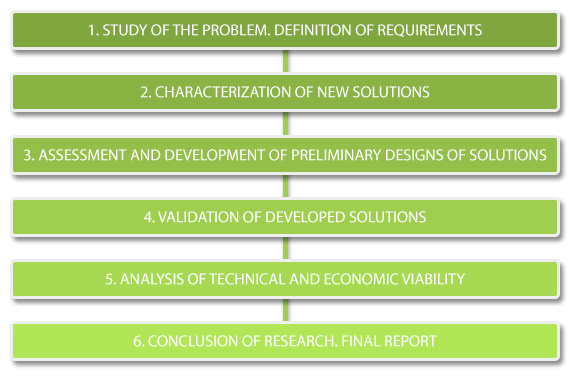

AEROVIAV project will be divided into 6 work activities, as shown in the following diagram, which will ensure that each of the objectives initially set are achieved:

Activity 1. Study of the problem. Definition of requirements.

The aim of this activity is to study the phenomenon of ballast pick-up establishing the technical factors involved (train speed, platform vibration, condition of the railroad, location of stones, etc.) in order to determine the technical and functional properties required for the solutions developed in this project whose aim is to eliminate it. First of all, a state of the art of the problem of ballast pick-up and the current corrective measures that exist will be made, to determine the technical characteristics that our developments should fulfill, ranging from physical-chemical aspects such as particle cohesion ability or hardening time and conditions, to morphological aspects of suitability to the rest of the components of the railroad.

This activity is divided into three tasks:

T. 1.1. Study of the problem of ballast pick-up and current corrective measures.

T. 1.2. Definition of requirements of new solutions.

T. 1.3. Existing regulation and trials for solutions assessment.

Activity 2. Characterization of new solutions.

The aim of this activity is to pre-design and characterize the solutions that we are going to develop in the project in order to assess these designs and select the optimal ones for their later assessment by CFD models. Thus, in this activity new solutions will be designed according to the minimum necessary aspects related

to each of them, such as: Physical-chemical properties, penetration ability, resistance to adverse environmental conditions , hardening time and conditions, morphology, assembly and disassembly easiness, anchorage systems, etc.

This activity consists on the following tasks:

T.2.1. Characterization of physical solution.

T.2.2. Characterization of chemical solution.

Activity 3. Assessment and development of preliminary designs of solutions.

The aim of this activity is to carry out a first stage validation of the developed technology through numerical models common to both suggested solutions (physical and chemical).

In this activity the effectiveness of the chemical solution will be also validated through preliminary laboratory trials to assess different aspects of it, in order to carry out an assessment of the two technologies through numerical simulations. Finally, a test campaign on scale of 1 to 1 will be conducted in the wind tunnel emulating a stretch of railroad on ballast in order to measure factors such as speed wind flow that occurs on the railroad after vehicles and taking measurements on acceleration on the ballast layer of the maximum speed reached by this material.

This activity comprises the following tasks:

T.3.1. Preliminary laboratory trials of chemical solution.

T. 3.2. Simulation of ballast performance in designed situations.

T.3.3. Analysis of the results obtained, optimization and selection of best solutions for their validation.

T. 3.4. Development of selected solutions.

Activity 4. Validation of developed solutions.

The aim of this task is the assessment on real scale of our solutions in order to minimize aerodynamic effects on high speed railway lines on ballast, based on three possible settings: without a support solution, with a physical solution and with a chemical solution.

Acciona and the Canary Islands Foundation ITER will carry out the tests in the ITER Wind Tunnel under specific speed and turbulence conditions in order to study the behaviour of ballast under three possible situations: without integrated solution, with an applied ballast binder and with physical solution on the railway ties.

The tasks comprised in this activity are:

T.4.1. Ballast tests in the wind tunnel with physical solution.

T.4.2. Ballast tests in the wind tunnel with chemical solution

T. 4.3. Development of demonstrators of both solutions for their subsequent validation in a stretch of railroad.

T. 4.4. Demonstrators tests in real operating conditions.

T. 4.5. Cross-check of outcome of the four validation phases.

Activity 5. Analysis of technical-economic viability.

The aim of this task is to assess the technical and economic viability of our developed and validated products, as well as mechanisms of application of the chemical solution. At this stage a technical and economic viability study will be carried out analysing commercial competitiveness of new products from an economic point of view, establishing the necessary strategies to foster commercialisation, analysing the future market positioning of developed thechnologies, comparing them with the existing ones. Cuevas will determine an implementation guidance of the developed technology in order to unify its operational.

Activity 6. Conclusion of Research and Development. Final Report.

The aim of this task is to collect the conclusions obtained throughout the research carried out in the project and to develop a final document containing the most relevant aspects found as well as a few suggestions in case of future developments derived from this AEROVIAV project.

In this final phase, all the project members will share the conclusions obtained from the project execution, reflecting aspects such as the problems encountered in its development, improvements obtained to the premises initially established, aspects to be improved, trial results, etc. On the basis of all that information, ACCIONA will draw up a report containing all the experience carried out, the valuation of the solutions obtained and some suggestions in case of future developments derived from it.